Slow sand filtration water treatment plants

Practical Action

OPERATION AND MAINTENANCE

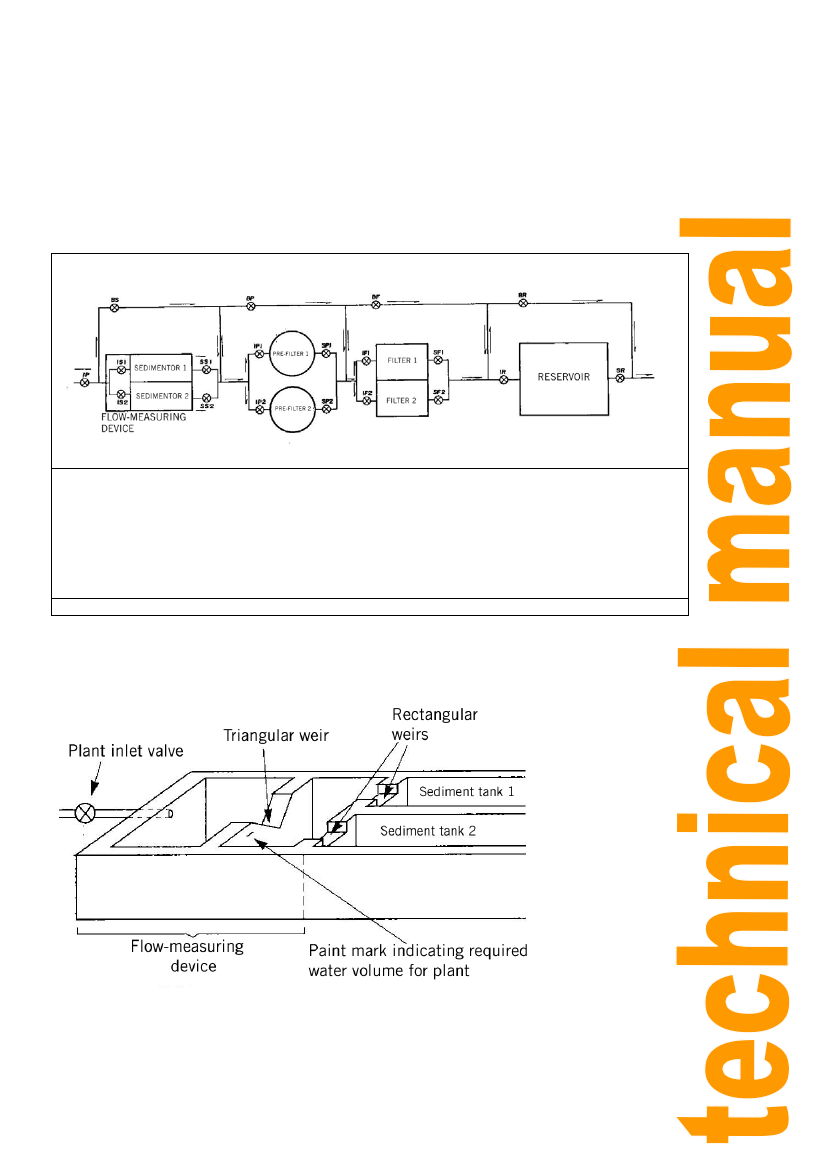

A flow-measuring device should be installed at the entrance to the treatment plant, as well as

a corresponding inlet valve to regulate the operating flow in the plant.

Below is a valve scheme for the conveyance of treated water. The bypass valves (B) enable

the plant to continue operating even when a unit is out of service.

P Plant entrance

IS 1 Entrance to sedimentator 1

IS 2 Entrance to sedimentator 2

SS 1 Sedimentator 2 outlet

SS2 Sedimentator 2 outlet

BS By pass sedimentators

IP 1 Entrance to pre-filter 1

SP1 Pre-filter 1 outlet

IP2 Entrance to pre-filter 2

SP2 Pre-filter 2 outlet

BP Pre-filter Bypass

IF1: Entrance to filter 1

F1 Filter 1 outlet

IF2 Entrance to filter 2

SF2 Filter 2 outlet

BF Filter by pass

IR Reserved income

SR Reservoir outlet

BR Reservoir by pass

VALVE SCHEME FOR TREATED WATER CONVEYANCE

For the flow-measuring device, a triangular weir and two rectangular weirs are recommended,

as shown in the figure.

In order to regulate the flow, the IP inlet valve is switched on until the water in the triangular

weir reaches the paint mark, which indicates the plant’s operating flow. The rectangular

weirs serve to make sure that the water enters the two sediment tanks evenly. Two simple

wooden sluice gates serve the purpose of the IS1 and IS2 valves, shutting off water flow into

a sediment tank during maintenance.

18